DATE

February 2017

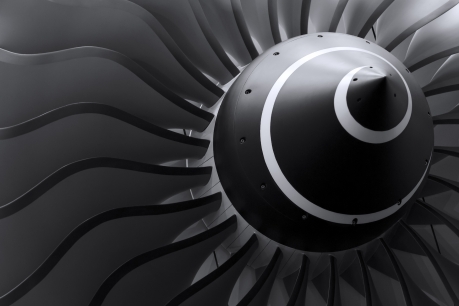

Radical operations boost: Double the output

A leading supplier of high-tech aircraft components doubled the output of a complex assembly in six-months’ time.

Challenge

Hands-on operational turnaround and set-up of a new assembly line for a worldwide leader in complex structural aerospace parts in the context of increasing pressure through volume increases, price pressure and late deliveries.

Approach

We followed a four-step “LEAN” approach:

- Document reality: identify issues by walking the shop floor to “see” the current state

- Plan countermeasures: through a series of focused kaizen events, define the future state

- Implement countermeasures: focus on pragmatic, easy-to-implement solutions

- Assess results and coach the team

Value

Within six months, the client managed to double its output using the newly designed and implemented assembly line and corresponding governance principles. The hands-on approach resulted in optimal buy-in from the client’s teams as well as actionable recommendations.

Radical operations boost: Double the output

A leading supplier of high-tech aircraft components doubled the output of a complex assembly in six-months’ time.

DATE

February 2017

Challenge

Hands-on operational turnaround and set-up of a new assembly line for a worldwide leader in complex structural aerospace parts in the context of increasing pressure through volume increases, price pressure and late deliveries.

Approach

We followed a four-step “LEAN” approach:

- Document reality: identify issues by walking the shop floor to “see” the current state

- Plan countermeasures: through a series of focused kaizen events, define the future state

- Implement countermeasures: focus on pragmatic, easy-to-implement solutions

- Assess results and coach the team

Value

Within six months, the client managed to double its output using the newly designed and implemented assembly line and corresponding governance principles. The hands-on approach resulted in optimal buy-in from the client’s teams as well as actionable recommendations.