Rethinking product connectivity

How data can transform services and customer experience

In a data-driven world, product manufacturers have a stark choice – either digitize to become more flexible and customer-centric or be sidelined by nimbler competitors. They need to embrace the transformative opportunities that data and the Internet of Things bring to add value to their offerings and change their business models.

All businesses understand the vital importance of collecting, analyzing, and acting on data to enable:

-

New business models, such as offering as-a-service or outcome-based pricing, and entering the Industrial Metaverse

-

Greater innovation through new services that create new revenue streams

-

An improved customer experience

Product connectivity is the foundation of successful data-driven business models for product manufacturers, enabling access to the right data at the right time. Yet, adding a digital layer to physical products is challenging at a strategic level, requiring close coordination with overall digital strategy; new, multidisciplinary capabilities; and deep understanding of a complex, fast-changing product/supplier ecosystem.

Connectivity has to be driven by a digital strategy, not technical considerations. However, many organizations struggle to define and agree their digital ambitions, which holds back necessary transformation.

How can business leaders overcome these challenges at a strategic level and become data-driven – before rivals seize the opportunity? This article explains how to reap the benefits of seamless, transformative product connectivity to digitalize how companies operate.

Operating in an ever-more connected world

Product connectivity is not new, but often has not been handled strategically or holistically by organizations or linked to digital strategy. As data and digitization become central to company strategies, this must change, demanding an overarching approach to product connectivity.

An accelerating market

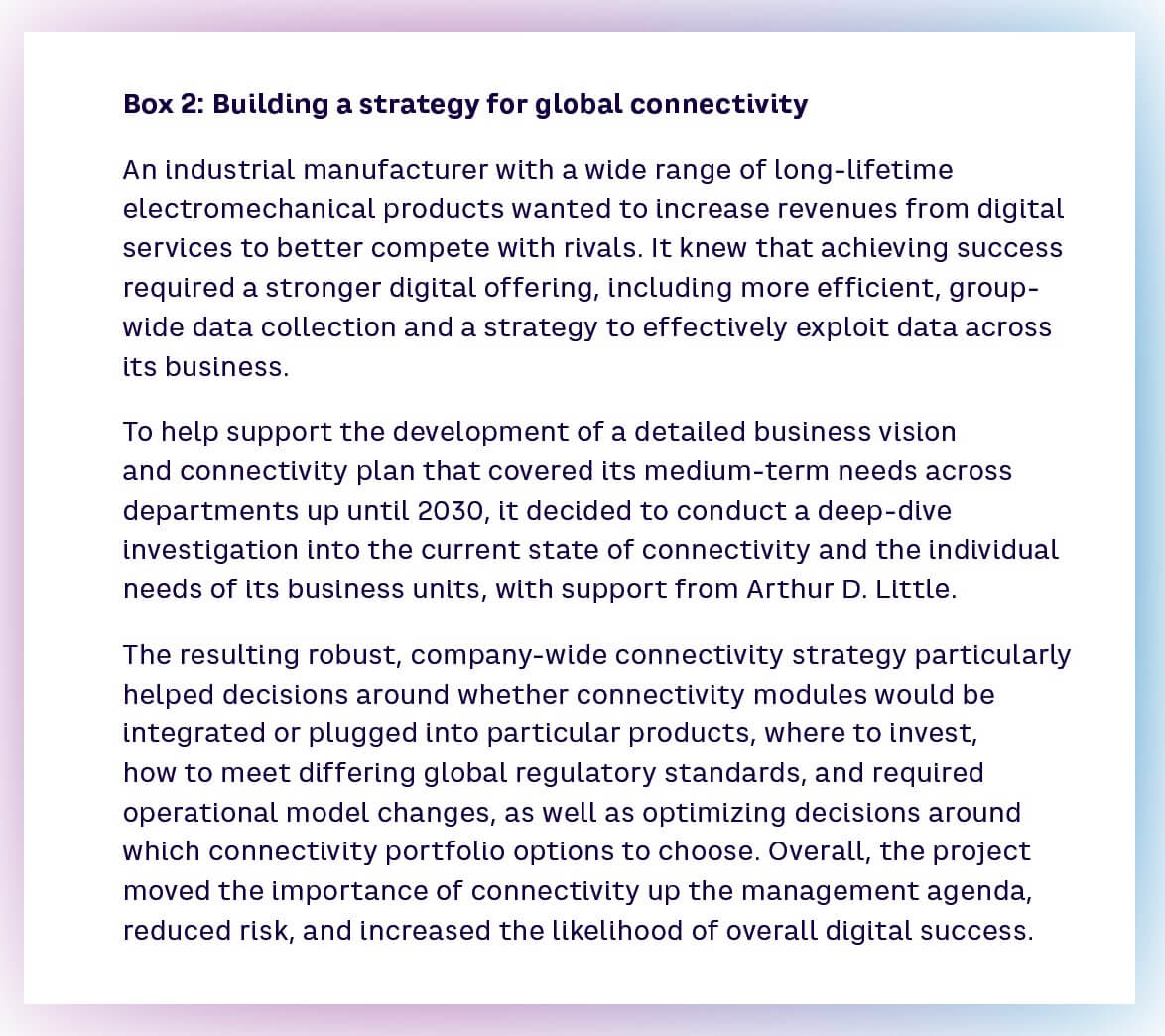

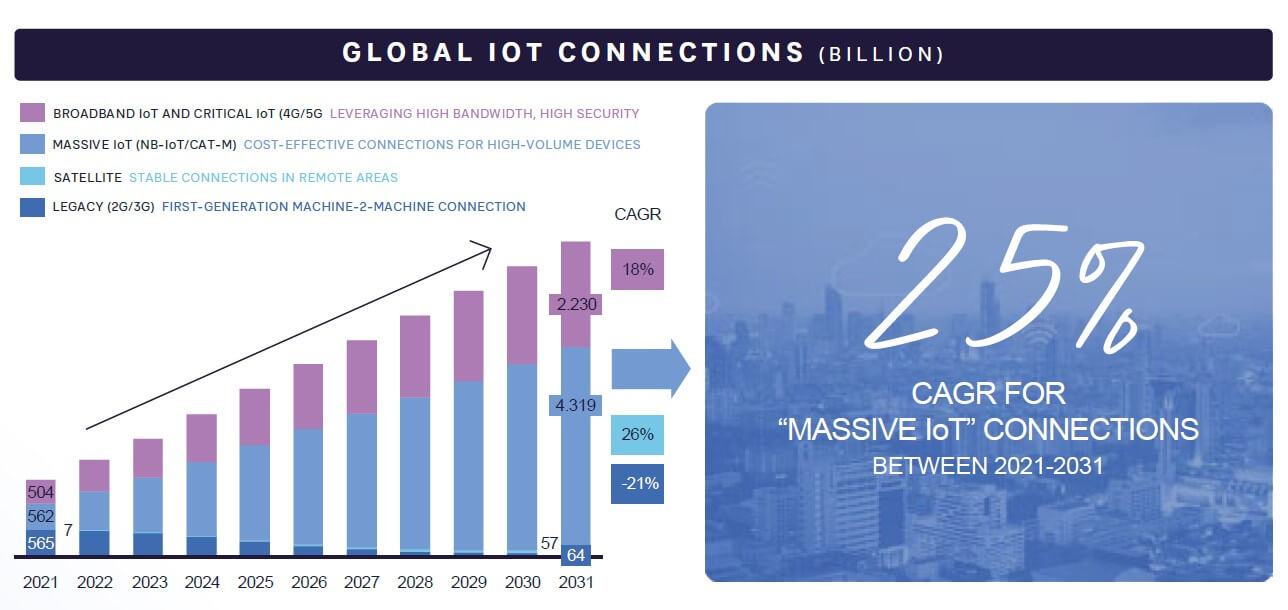

The Internet of Things (IoT) is becoming table stakes for product manufacturers. Ninety-nine percent of companies in ADL’s 2022 IoT survey have either implemented or are piloting product connectivity, with 48 percent increasing their spend year on year.[1] Altogether 6.6 billion IoT devices are expected to be connected globally by 2031, as shown in Figure 1.

1. The opportunities of connectivity

Product connectivity underpins transformation through the timely collection and sharing of data. It delivers opportunities in four areas:

2. Creating new business models

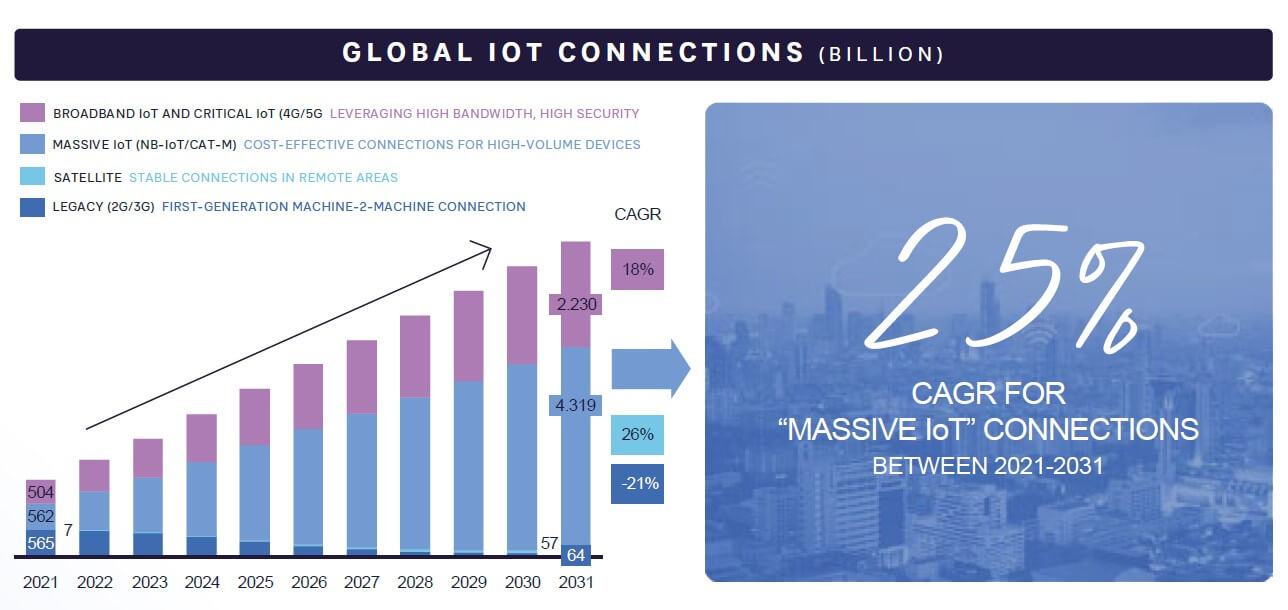

Seventy-five percent of companies surveyed by ADL see product connectivity enabling new working models. These include “as a service” business models, new revenue streams based on product data and outcome-based models, as described in Selling customer outcomes – A business model transformed (Prism S1 2022). For example, Hitachi’s Lumada IoT platform connects its products and systems, from industrial machinery and trains to IT systems. This enables it to offer new services to clients globally.

3. Enabling a better customer experience

Seventy percent of businesses in the ADL study said connectivity was key to meeting changing customer requirements. For example, Ericsson, telematics provider ZF, and Orange Belgium introduced a new truck and trailer monitoring and driver assistance service for freight companies. Together these provide cost savings of EUR 876,000 for a mid-size truck transport company, 6 percent of total annual spend.

4. Greater efficiency

Data increases efficiency by enabling predictive maintenance, reducing downtime, and optimizing operations. For example, Caterpillar’s Cat Connect solution uses the data from technology-equipped construction vehicles to enable predictive maintenance while providing greater insight into customer operations.

5. Future innovation

Product data can be used to train AI algorithms and carry out in-depth analytics to predict the future and create new products and services. Demonstrating the benefits, food company Farmer’s Fridge has deployed a network of smart fridges stocked with fresh meals. Fridges are restocked based on an algorithm that learns customers’ food preferences, reducing waste and increasing satisfaction by supplying what people want to eat.

The challenges to strategic connectivity success

Multi-product manufacturers face multiple challenges to creating and deploying a successful product connectivity strategy:

The need to link to digital strategy

Connectivity decisions need to start, and flow from, the company’s digital strategy. Defining digital strategy and ensuring buy-in is therefore vital, but can be difficult for manufacturers that are used to operating in an analog world. They need to add new competences, ways of working, and change culture to become digital-first across the organization. Additionally, businesses need to effectively define the value proposition and logic for incorporating connectivity into their products in order to unlock investment. This can be challenging in that traditional ROI calculations might not show value, as returns come in the form of difficult-to-quantify new opportunities.

A complex, fragmented, and fast-evolving supplier landscape

Complexity leads to the wrong technology choices being made (such as around connectivity type, sensors, IoT platform, and applications). The risk of making the wrong choice around suppliers and technology not only is expensive, but potentially limits future options and undermines opportunities for value creation. Companies also need to strike the right balance between the differing lifetimes of products and the connectivity technologies deployed within them, and understand the trade-offs between adopting off-the-shelf products versus investing in more specialized products built to their requirements. Sixty-nine percent of respondents in ADL’s IoT Market Study mentioned that the high complexity of implementing solutions was a key challenge with the IoT, while 38 percent said they had difficulties in justifying the business case around IoT investments.

The requirement for new capabilities

Adding product connectivity requires new digital capabilities, partnerships, and skills. Companies must create new ecosystems and teams to provide the organization and resources to manage and integrate product capabilities at a strategic and company-wide level. Aircraft manufacturer Airbus partnered with Palantir Technologies to create its Skywise data platform, which uses IoT sensor information for predictive maintenance, monitoring, and benchmarking of aircraft fleet performance.

Balancing business unit and overall requirements

Companies providing multiple product types must meet the differing connectivity needs of every business unit and product that they supply. Equally, they must balance departmental needs with corporate standards to ensure economies of scale and efficient access to consistent, high-quality data. This requires a portfolio approach, rather than expecting one connectivity solution to meet every requirement.

Differing standards and regulations across the globe

Wireless standards vary between markets, for example, with LTE-M dominant in the US and NB-IoT most used in China. This requires organizations to make strategic choices, particularly in light of geopolitical concerns between the US and China, especially around cybersecurity. Fifty percent of companies surveyed mentioned that security concerns were a key challenge with connectivity and the IoT.

On the regulatory side, businesses need to navigate a thicket of different legislation put in place by the EU (such as the EU Radio Equipment Directive Delegated Act on Cybersecurity) and the US (at both a federal and state level – California and New York have created cybersecurity regulations, for example). Cybersecurity also ties into customer concerns and requirements around protecting personal data and meeting security standards.

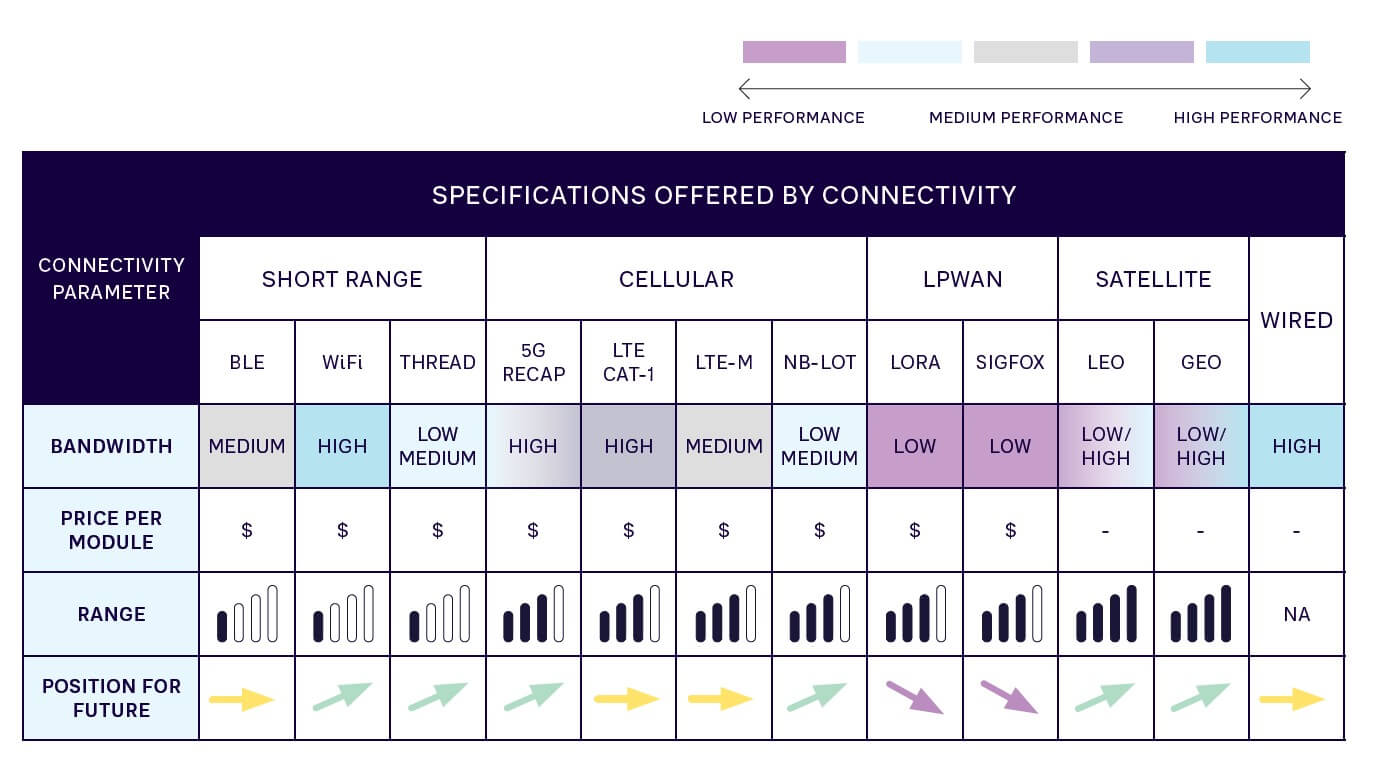

Embracing the connectivity opportunity

Product manufacturers need to put in place a holistic strategy to fully embrace the connectivity opportunity and the transformational benefits it potentially delivers. This requires a focus on understanding the ecosystem and then building a strategy based on the specific needs of the company and its current and future customers.

There are three groups of themes for companies to understand:

1. Technology themes

The proliferation and emergence of different connectivity technologies and standards enables new use cases. However, it also creates more choices and decisions for both companies and customers as they look to cover all products and regions.

Companies must choose carefully which platforms to create compatibility with. Nearly two-thirds (65 percent) of companies in the ADL IoT study pointed to difficulties with technical integration as a key challenge to connectivity success.

2. Regulatory themes

The growing importance of cybersecurity will affect manufacturers profoundly. Failing to keep connected products secure impacts reputation, leads to legal/regulatory challenges, and can ultimately provide a backdoor into corporate systems. A focus on cybersecurity must run through ways of working and product design, covering areas such as vulnerability and data management, continuous over-the-air (OTA) updates, and usage of open-source code or products from partners.

Allied to cybersecurity, growing US/China tensions around technology mean that global companies will need to develop a portfolio of regional solutions. To mitigate risk they should develop tools that enable them to understand the compliance burden of specific features being integrated into their products in specific regions.

3. Business themes

Product connectivity is considered a standard feature due to increasing customer adoption and the fact that data is becoming a critical business resource. Manufacturers have no option but to integrate it within products, despite it being challenging to measure ROI at a business level.

Connectivity therefore needs to be built on overall digital strategy. Companies must create future-proof data competencies and connectivity infrastructure built on their digital foundations. They need to develop and define what data is needed and why, including for R&D and innovation purposes alongside existing business cases. For example, automotive company Hyundai has invested heavily in software development to create its Bluelink connected car operating system, which includes telematics and remote start features.

By understanding these themes and answering three key questions – why, what, how – manufacturing companies can transform their business models, services, and customer experience through effective product connectivity.

Why does my company strategy require connectivity?

First, companies must define why they require connectivity in their products as part of their digital strategy. This will vary depending on:

-

Their desired position in the market

-

Their value proposition for end users

-

Which digital solutions can be enabled through connectivity to deliver this value proposition

-

How connectivity can be used to disrupt existing business models

-

Particular use cases and the data each of these require

-

The best business model(s) to capitalize on this value proposition

What connectivity technologies do we need for the future?

When the “why” is defined, the “what” can be created, in terms of connectivity technologies and sensors that enable the desired use cases and value propositions.

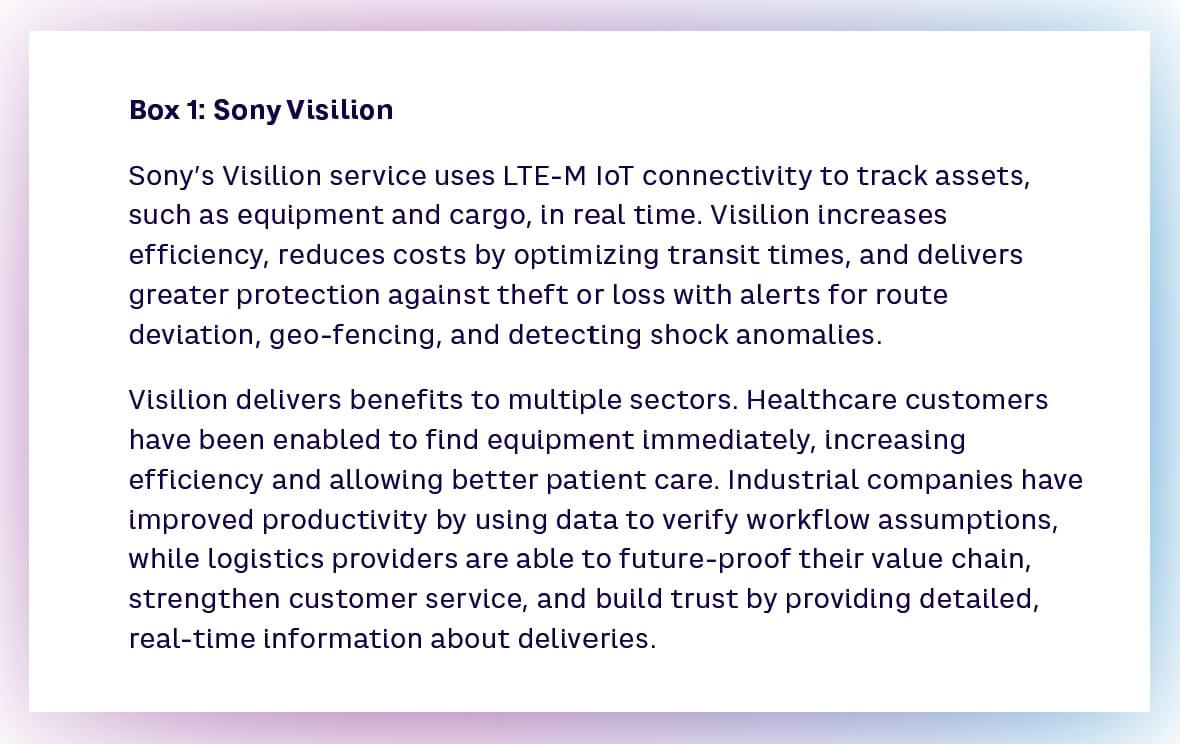

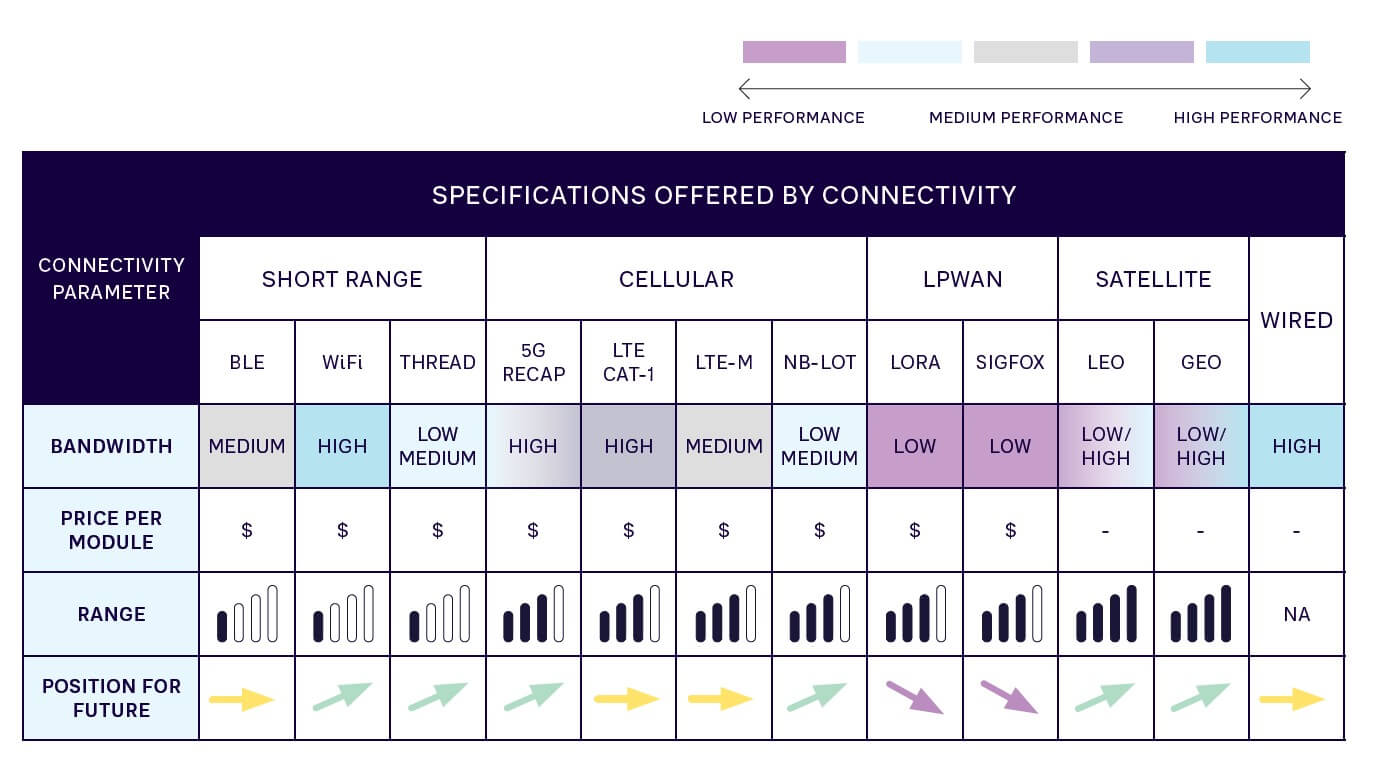

Every product may have different requirements (Figure 2). Companies should therefore define a portfolio of applicable technologies for business units to choose from. A one-size-fits-all approach will not deliver sufficient value. However, this needs to be balanced against corporate standards and achieving economies of scale. Companies must focus on factors such as:

-

Ensuring interoperability and ease of integration

-

Aligning connectivity requirements with customer experience goals

-

Building a device and connectivity management strategy

-

Evaluating the cost/benefit of retrofitting the installed base. This could potentially cover millions of sensors in brownfield implementations

How do we build the capabilities needed to deliver connectivity?

When the “why” and “what” are defined, decisions can be taken around how capabilities are built and deployed. This requires a transformational change to ensure that the resources, skills, and digital-first ways of working are in place to ensure success.

Businesses should:

-

Build an organization ready to support millions of connected devices

-

Further integrate connectivity into product development and create the ways of working needed to maximize value

-

Explore how to integrate data into the business model and product development

-

Find and manage a network of new partners to support connectivity

-

Ensure compliance with the complex regulatory landscape

-

Evaluate whether the wider IT stack is fit for future needs

-

Work to safeguard connectivity investments even if ROI discussions are initially challenging

Insights for the Executive

-

Connectivity decisions may seem technical and tactical. However, given the importance of data to building new business models and services and the cost of incorrect choices, strategy must be driven from the top. Start with digital strategy.

-

Adopt a portfolio approach to cover all business unit needs and unify business units behind choices.

-

Ensure a clear link between the connectivity and data strategies, business model, and customer experience. Leverage connectivity opportunities across the organization - in product development, new business models, skills and resources, and future strategy.

-

Understand and plan for the potential impact of current and future regulation, particularly around how geopolitical rivalry may limit technology choices in specific markets.

-

Participate strongly in relevant ecosystems, orchestrating other players where appropriate.

-

Act now, moving quickly to seize opportunities before competitors do.

Note

[1] The ADL 2022 Internet of Things study surveyed global CXOs from the automotive, transport and logistics, manufacturing, and energy and utility sectors.

Rethinking product connectivity

How data can transform services and customer experience

DATE

In a data-driven world, product manufacturers have a stark choice – either digitize to become more flexible and customer-centric or be sidelined by nimbler competitors. They need to embrace the transformative opportunities that data and the Internet of Things bring to add value to their offerings and change their business models.

All businesses understand the vital importance of collecting, analyzing, and acting on data to enable:

-

New business models, such as offering as-a-service or outcome-based pricing, and entering the Industrial Metaverse

-

Greater innovation through new services that create new revenue streams

-

An improved customer experience

Product connectivity is the foundation of successful data-driven business models for product manufacturers, enabling access to the right data at the right time. Yet, adding a digital layer to physical products is challenging at a strategic level, requiring close coordination with overall digital strategy; new, multidisciplinary capabilities; and deep understanding of a complex, fast-changing product/supplier ecosystem.

Connectivity has to be driven by a digital strategy, not technical considerations. However, many organizations struggle to define and agree their digital ambitions, which holds back necessary transformation.

How can business leaders overcome these challenges at a strategic level and become data-driven – before rivals seize the opportunity? This article explains how to reap the benefits of seamless, transformative product connectivity to digitalize how companies operate.

Operating in an ever-more connected world

Product connectivity is not new, but often has not been handled strategically or holistically by organizations or linked to digital strategy. As data and digitization become central to company strategies, this must change, demanding an overarching approach to product connectivity.

An accelerating market

The Internet of Things (IoT) is becoming table stakes for product manufacturers. Ninety-nine percent of companies in ADL’s 2022 IoT survey have either implemented or are piloting product connectivity, with 48 percent increasing their spend year on year.[1] Altogether 6.6 billion IoT devices are expected to be connected globally by 2031, as shown in Figure 1.

1. The opportunities of connectivity

Product connectivity underpins transformation through the timely collection and sharing of data. It delivers opportunities in four areas:

2. Creating new business models

Seventy-five percent of companies surveyed by ADL see product connectivity enabling new working models. These include “as a service” business models, new revenue streams based on product data and outcome-based models, as described in Selling customer outcomes – A business model transformed (Prism S1 2022). For example, Hitachi’s Lumada IoT platform connects its products and systems, from industrial machinery and trains to IT systems. This enables it to offer new services to clients globally.

3. Enabling a better customer experience

Seventy percent of businesses in the ADL study said connectivity was key to meeting changing customer requirements. For example, Ericsson, telematics provider ZF, and Orange Belgium introduced a new truck and trailer monitoring and driver assistance service for freight companies. Together these provide cost savings of EUR 876,000 for a mid-size truck transport company, 6 percent of total annual spend.

4. Greater efficiency

Data increases efficiency by enabling predictive maintenance, reducing downtime, and optimizing operations. For example, Caterpillar’s Cat Connect solution uses the data from technology-equipped construction vehicles to enable predictive maintenance while providing greater insight into customer operations.

5. Future innovation

Product data can be used to train AI algorithms and carry out in-depth analytics to predict the future and create new products and services. Demonstrating the benefits, food company Farmer’s Fridge has deployed a network of smart fridges stocked with fresh meals. Fridges are restocked based on an algorithm that learns customers’ food preferences, reducing waste and increasing satisfaction by supplying what people want to eat.

The challenges to strategic connectivity success

Multi-product manufacturers face multiple challenges to creating and deploying a successful product connectivity strategy:

The need to link to digital strategy

Connectivity decisions need to start, and flow from, the company’s digital strategy. Defining digital strategy and ensuring buy-in is therefore vital, but can be difficult for manufacturers that are used to operating in an analog world. They need to add new competences, ways of working, and change culture to become digital-first across the organization. Additionally, businesses need to effectively define the value proposition and logic for incorporating connectivity into their products in order to unlock investment. This can be challenging in that traditional ROI calculations might not show value, as returns come in the form of difficult-to-quantify new opportunities.

A complex, fragmented, and fast-evolving supplier landscape

Complexity leads to the wrong technology choices being made (such as around connectivity type, sensors, IoT platform, and applications). The risk of making the wrong choice around suppliers and technology not only is expensive, but potentially limits future options and undermines opportunities for value creation. Companies also need to strike the right balance between the differing lifetimes of products and the connectivity technologies deployed within them, and understand the trade-offs between adopting off-the-shelf products versus investing in more specialized products built to their requirements. Sixty-nine percent of respondents in ADL’s IoT Market Study mentioned that the high complexity of implementing solutions was a key challenge with the IoT, while 38 percent said they had difficulties in justifying the business case around IoT investments.

The requirement for new capabilities

Adding product connectivity requires new digital capabilities, partnerships, and skills. Companies must create new ecosystems and teams to provide the organization and resources to manage and integrate product capabilities at a strategic and company-wide level. Aircraft manufacturer Airbus partnered with Palantir Technologies to create its Skywise data platform, which uses IoT sensor information for predictive maintenance, monitoring, and benchmarking of aircraft fleet performance.

Balancing business unit and overall requirements

Companies providing multiple product types must meet the differing connectivity needs of every business unit and product that they supply. Equally, they must balance departmental needs with corporate standards to ensure economies of scale and efficient access to consistent, high-quality data. This requires a portfolio approach, rather than expecting one connectivity solution to meet every requirement.

Differing standards and regulations across the globe

Wireless standards vary between markets, for example, with LTE-M dominant in the US and NB-IoT most used in China. This requires organizations to make strategic choices, particularly in light of geopolitical concerns between the US and China, especially around cybersecurity. Fifty percent of companies surveyed mentioned that security concerns were a key challenge with connectivity and the IoT.

On the regulatory side, businesses need to navigate a thicket of different legislation put in place by the EU (such as the EU Radio Equipment Directive Delegated Act on Cybersecurity) and the US (at both a federal and state level – California and New York have created cybersecurity regulations, for example). Cybersecurity also ties into customer concerns and requirements around protecting personal data and meeting security standards.

Embracing the connectivity opportunity

Product manufacturers need to put in place a holistic strategy to fully embrace the connectivity opportunity and the transformational benefits it potentially delivers. This requires a focus on understanding the ecosystem and then building a strategy based on the specific needs of the company and its current and future customers.

There are three groups of themes for companies to understand:

1. Technology themes

The proliferation and emergence of different connectivity technologies and standards enables new use cases. However, it also creates more choices and decisions for both companies and customers as they look to cover all products and regions.

Companies must choose carefully which platforms to create compatibility with. Nearly two-thirds (65 percent) of companies in the ADL IoT study pointed to difficulties with technical integration as a key challenge to connectivity success.

2. Regulatory themes

The growing importance of cybersecurity will affect manufacturers profoundly. Failing to keep connected products secure impacts reputation, leads to legal/regulatory challenges, and can ultimately provide a backdoor into corporate systems. A focus on cybersecurity must run through ways of working and product design, covering areas such as vulnerability and data management, continuous over-the-air (OTA) updates, and usage of open-source code or products from partners.

Allied to cybersecurity, growing US/China tensions around technology mean that global companies will need to develop a portfolio of regional solutions. To mitigate risk they should develop tools that enable them to understand the compliance burden of specific features being integrated into their products in specific regions.

3. Business themes

Product connectivity is considered a standard feature due to increasing customer adoption and the fact that data is becoming a critical business resource. Manufacturers have no option but to integrate it within products, despite it being challenging to measure ROI at a business level.

Connectivity therefore needs to be built on overall digital strategy. Companies must create future-proof data competencies and connectivity infrastructure built on their digital foundations. They need to develop and define what data is needed and why, including for R&D and innovation purposes alongside existing business cases. For example, automotive company Hyundai has invested heavily in software development to create its Bluelink connected car operating system, which includes telematics and remote start features.

By understanding these themes and answering three key questions – why, what, how – manufacturing companies can transform their business models, services, and customer experience through effective product connectivity.

Why does my company strategy require connectivity?

First, companies must define why they require connectivity in their products as part of their digital strategy. This will vary depending on:

-

Their desired position in the market

-

Their value proposition for end users

-

Which digital solutions can be enabled through connectivity to deliver this value proposition

-

How connectivity can be used to disrupt existing business models

-

Particular use cases and the data each of these require

-

The best business model(s) to capitalize on this value proposition

What connectivity technologies do we need for the future?

When the “why” is defined, the “what” can be created, in terms of connectivity technologies and sensors that enable the desired use cases and value propositions.

Every product may have different requirements (Figure 2). Companies should therefore define a portfolio of applicable technologies for business units to choose from. A one-size-fits-all approach will not deliver sufficient value. However, this needs to be balanced against corporate standards and achieving economies of scale. Companies must focus on factors such as:

-

Ensuring interoperability and ease of integration

-

Aligning connectivity requirements with customer experience goals

-

Building a device and connectivity management strategy

-

Evaluating the cost/benefit of retrofitting the installed base. This could potentially cover millions of sensors in brownfield implementations

How do we build the capabilities needed to deliver connectivity?

When the “why” and “what” are defined, decisions can be taken around how capabilities are built and deployed. This requires a transformational change to ensure that the resources, skills, and digital-first ways of working are in place to ensure success.

Businesses should:

-

Build an organization ready to support millions of connected devices

-

Further integrate connectivity into product development and create the ways of working needed to maximize value

-

Explore how to integrate data into the business model and product development

-

Find and manage a network of new partners to support connectivity

-

Ensure compliance with the complex regulatory landscape

-

Evaluate whether the wider IT stack is fit for future needs

-

Work to safeguard connectivity investments even if ROI discussions are initially challenging

Insights for the Executive

-

Connectivity decisions may seem technical and tactical. However, given the importance of data to building new business models and services and the cost of incorrect choices, strategy must be driven from the top. Start with digital strategy.

-

Adopt a portfolio approach to cover all business unit needs and unify business units behind choices.

-

Ensure a clear link between the connectivity and data strategies, business model, and customer experience. Leverage connectivity opportunities across the organization - in product development, new business models, skills and resources, and future strategy.

-

Understand and plan for the potential impact of current and future regulation, particularly around how geopolitical rivalry may limit technology choices in specific markets.

-

Participate strongly in relevant ecosystems, orchestrating other players where appropriate.

-

Act now, moving quickly to seize opportunities before competitors do.

Note

[1] The ADL 2022 Internet of Things study surveyed global CXOs from the automotive, transport and logistics, manufacturing, and energy and utility sectors.